Written By:

Scott McAuley

Scott is the IT Director of Texas Management Group, and has been in the IT industry for 25 years.

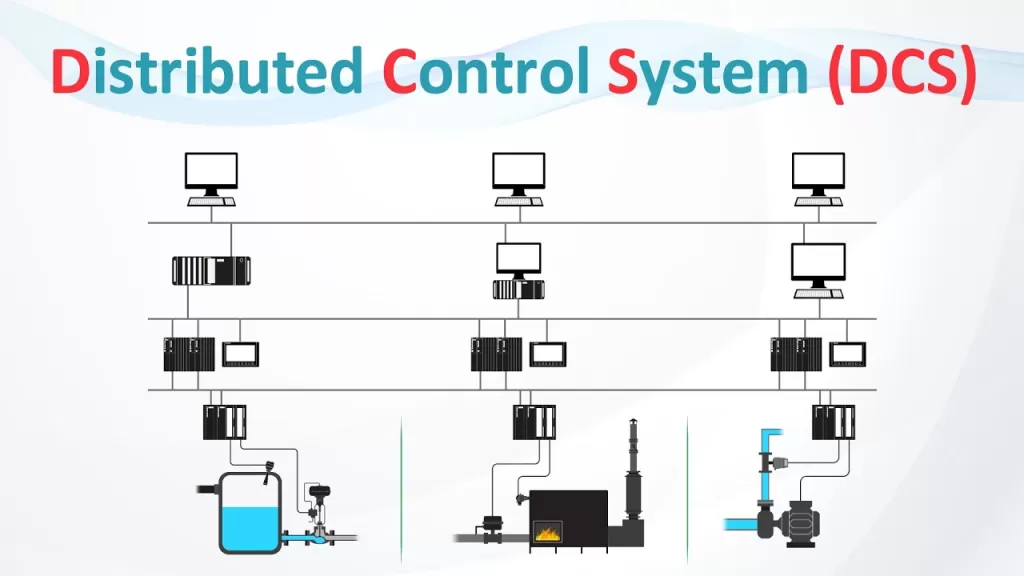

In the world of industrial automation, managing complex processes efficiently is key. That’s where a Distributed Control System (DCS) comes in. But what exactly is a DCS, and why is it so essential?

A Distributed Control System is designed to automate and control large-scale industrial processes, ensuring precision, reliability, and safety.

With its decentralized structure, a DCS allows different components to work together seamlessly, making it a critical tool for industries like manufacturing, energy, and chemical processing.

In this article, we’ll break down what a Distributed Control System is and explore the necessary components that make it function effectively.

Let’s explore the core elements that bring a DCS to life and how they support industrial operations.

Key Takeaways

- A Distributed Control System (DCS) automates complex industrial processes, ensuring precision, reliability, and safety across industries like manufacturing, energy, and chemical processing.

- DCS streamlines production workflows through automation and real-time monitoring, improving efficiency, reducing downtime, and enabling seamless adjustments during operations.

- Enhanced data management in DCS supports decision-making by gathering and analyzing real-time and historical data, offering valuable insights for operational improvements.

- DCS improves system safety and reliability by continuously monitoring operations, detecting inefficiencies, and implementing control actions to prevent equipment failure and ensure smooth functioning.

- Scalability of DCS allows for future growth by integrating new technologies without disrupting existing operations, ensuring long-term adaptability and efficiency.

Table of Contents

What is a Distributed Control System (DCS)?

In the world of industrial automation, the Distributed Control System (DCS) plays a crucial role. It connects multiple control functions in complex environments like factories.

DCS is different from other automation systems because it handles a wide range of process controls. It revolutionized how plants operate by making processes more reliable and flexible.

A DCS integrates all parts of a plant’s operations into one cohesive system. This allows for more detailed and powerful automation that fits with modern technology and industry needs.

5 Levels of Distributed Control System (DCS)

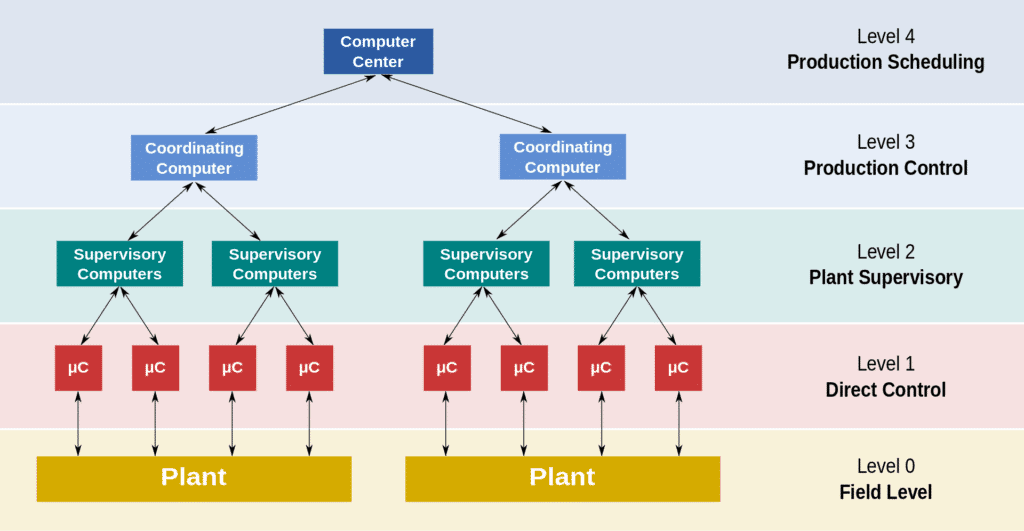

A Distributed Control System (DCS) is structured in hierarchical levels, each serving a specific function.

Let’s explore the 5 levels that optimize control, monitoring, and decision-making in industrial processes:

| Level | Description |

|---|---|

| Level 0 | Field Level: This level comprises the physical field devices such as sensors and actuators that directly interact with the controlled processes. These devices measure parameters like temperature, pressure, flow, etc., and actuate valves, motors, and other equipment based on control signals. |

| Level 1 | Direct Control: At this level, the control loops are executed directly by local controllers such as Programmable Logic Controllers (PLCs) or Remote Terminal Units (RTUs). These controllers receive input from field devices, execute control algorithms, and send output signals to actuate devices for process control. |

| Level 2 | Plant Supervisory: Plant supervisory level involves supervisory control systems that aggregate data from multiple control loops and local controllers. This level provides a centralized interface for monitoring and controlling various processes within the plant. Supervisory systems often include Human-Machine Interface (HMI) software for operators to visualize processes and make control decisions. |

| Level 3 | Production Control: Production control systems manage and coordinate the overall operation of the plant. They optimize production schedules, allocate resources, and coordinate activities across different areas of the plant to maximize efficiency and productivity. Production control systems often integrate with plant supervisory systems to exchange data and coordinate operations. |

| Level 4 | Production Scheduling: Production scheduling involves long-term planning and scheduling of production activities based on demand forecasts, resource availability, and other factors. This level interfaces with enterprise-level systems such as Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems to align production schedules with overall business objectives and strategies. |

How is a DCS Used?

In environments like nuclear power plants, a Distributed Control System (DCS) plays a key role. It ensures continuous control loops that keep operations safe and efficient.

A DCS handles both continuous and batch processes with high precision. It uses redundant communication networks to maintain control, even during failures.

These networks ensure seamless communication and uninterrupted control actions. A DCS also stores vast amounts of data for trend analysis, legal compliance, and operational reviews.

Here’s how a DCS organizes its tasks:

Monitoring

Sensors continuously provide real-time feedback about the plant’s operation. This data allows the system to monitor performance and identify issues.

Control Actions

Based on this feedback, the DCS makes adjustments to the processes using actuators. These control actions ensure the plant runs smoothly and responds to changes.

Data Storage and Analysis

The system stores both current and historical data. This data is critical for analyzing trends, creating reports, and planning future improvements.

Communication

A strong communication system is essential for overall plant oversight. This ensures reliability and helps prevent disruptions during normal operations or emergencies.

DCS in Different Parts of a Nuclear Facility

The DCS is integrated across various parts of the nuclear facility. It ensures control and safety in different sections, as shown below:

| Facility Section | Control Loop Application | Redundancy Measures | Batch vs. Continuous |

|---|---|---|---|

| Reactor Control | Temperature and pressure regulation | Dual network pathways | Continuous |

| Fuel Handling | Automated fuel rod insertion | Multiple control systems | Batch |

| Waste Treatment | Radioactive waste processing | Redundant sensor arrays | Continuous and Batch |

| Cooling System | Coolant flow management | Backup power systems | Continuous |

| Emergency Shutdown | System-wide safety checks | Fail-safe communication protocols | N/A |

10 Uses of a Distributed Control System

The Distributed Control System (DCS) has changed how we manage and regulate in many fields. It combines the process control unit, programmable logic, and SCADA systems.

Here are the 10 uses of a distributed control system:

| Industry | Function | Benefit of DCS |

|---|---|---|

| Power Generation | Plant Management | Enhanced Safety & Efficiency |

| Manufacturing | Production Line Control | Consistent Product Quality |

| Water Treatment | Process Regulation | Accurate Treatment Processes |

| Building Management | Utility Regulation | Energy Savings & Comfort |

| Transportation | Logistics Coordination | Smooth Operation & Safety |

| Environmental Sector | Emissions & Waste Management | Sustainable Operations |

| Food & Beverage | Quality Assurance | Consumer Safety & Satisfaction |

| Pharmaceuticals | Medicine Manufacturing | Strict Purity & Compliance |

1. Industrial Automation

DCS systems in industrial automation handle many process control tasks. They make things more efficient by collecting data in real-time and using SCADA. The use of programmable logic controllers in DCS boosts productivity and reduces downtime.

2. Process Control

Using DCS for process control makes complex operations smoother. It ensures precise control and monitoring. Advanced control strategies provide flexibility in handling various industrial processes.

3. Power Plant Management

DCS systems are crucial for power plant management. They keep plants running safely and efficiently. They also integrate with SCADA systems for real-time operations and emergencies.

4. Manufacturing Operations

In manufacturing, DCS technology helps control production lines. It uses programmable logic for machinery, ensuring consistent product quality. It also allows for rapid changes in operations.

5. Water and Wastewater Management

DCS is vital for water and wastewater management. It controls treatment processes, pump operations, and chemical dosing accurately.

6. Building Automation

For building automation, DCS manages HVAC systems and other utilities. It makes buildings more comfortable and energy-efficient.

7. Transportation Systems

DCS improves transportation systems. It helps with traffic signals, railway signaling, and airport logistics. This ensures safe and consistent movement based on data.

8. Environmental Monitoring

Environmental monitoring benefits from DCS. It accurately controls emissions monitoring and waste management. This is crucial for keeping operations sustainable.

9. Food and Beverage Processing

DCS is used in food and beverage processing to control quality. It helps manage recipes and ensures consistency across batches. This is important for consumer safety and satisfaction.

10. Pharmaceutical Manufacturing

Pharmaceutical facilities depend on DCS for strict controls. These systems help in making medicines and vaccines. They ensure high standards of purity and compliance.

Importance of DCS in Industrial Automation

Distributed Control Systems (DCS) are at the heart of industrial automation. They streamline operations and increase efficiency across industries like oil, gas, chemicals, and pharmaceuticals.

Holistic Control with DCS

DCS goes beyond handling specific tasks. It manages entire industrial processes, providing a comprehensive control system for complex operations.

Seamless Integration with Automation Systems

A DCS seamlessly integrates with advanced automation technologies. This ensures smooth coordination and boosts production efficiency across various systems.

Scalability for Growing Industries

One of the key advantages of DCS is its scalability. Businesses can expand their systems without causing major disruptions or halting operations.

Enhanced Fault Tolerance

DCS offers exceptional fault tolerance due to its distributed nature. Even in the event of a component failure, the system continues operating with minimal downtime.

Continuous Process Optimization

DCS systems are designed to optimize continuous processes. They focus on improving efficiency and reducing waste to help industries reach their production goals.

Real-Time Data Handling and Analytics

DCS systems handle vast amounts of data efficiently, supporting real-time analytics. This enables companies to make smarter decisions and predict maintenance needs.

Distributed Control System (DCS) Components

A Distributed Control System (DCS) consists of multiple hardware and software components that work together to control and monitor industrial processes.

These components ensure seamless communication, data processing, and control execution across complex operations. Below are the 10 key hardware and software components of a DCS:

10 Hardware Components of DCS

- Controllers: Execute control algorithms and coordinate other hardware components by processing input data and sending commands to actuators.

- Input/Output (I/O) Modules: Facilitate communication between the DCS and field devices by converting analog or digital signals into digital data for processing.

- Communication Networks: Enable data exchange between controllers, I/O modules, operator consoles, and other components, ensuring system-wide communication.

- Operator Consoles: Provide a graphical interface for operators to monitor and control processes in real-time, displaying alarms and trends.

- Human-Machine Interface (HMI) Software: Allows operators to interact with the DCS via intuitive graphical interfaces, enhancing operational control and efficiency.

- Redundancy Systems: Ensure system reliability by providing backup mechanisms for critical components, preventing downtime and data loss.

- Power Supplies: Supply electrical power to DCS components, maintaining uninterrupted operation and protecting against power disruptions.

- Cabinets and Enclosures: Protect DCS hardware from environmental factors such as dust, moisture, and temperature fluctuations, ensuring equipment longevity.

- Field Devices: Include sensors, switches, and actuators installed in the field to monitor and control processes, interfacing with the DCS through I/O modules.

- Engineering Workstations: Used for system configuration, troubleshooting, and maintenance tasks, hosting software tools for DCS design and optimization.

10 Software Components of DCS

- Supervisory Control and Data Acquisition (SCADA) Software: Monitors and controls industrial processes by collecting and displaying real-time data from remote devices.

- Distributed Control System (DCS) Software: Provides the core control functionalities, including managing I/O devices and executing control algorithms.

- Human-Machine Interface (HMI) Software: Offers graphical interfaces for operators to monitor and control processes, displaying data, alarms, and control functions.

- Programmable Logic Controller (PLC) Software: Configures PLCs for machinery control, allowing the definition of logic sequences and control parameters.

- Configuration and Engineering Tools: Assist engineers in configuring and maintaining the DCS through programming, diagnostic, and optimization tools.

- Alarm Management Software: Helps operators prioritize and respond to alarms, providing tools for alarm configuration, suppression, and event documentation.

- Data Historian Software: Collects and analyzes historical process data, enabling performance monitoring, troubleshooting, and optimization.

- Asset Management Software: Tracks and manages the lifecycle of assets within the DCS, optimizing usage and maintenance scheduling.

- Simulation and Modeling Software: Enables virtual models of processes for testing control strategies, optimizing processes, and training operators.

- Integration Middleware: Facilitates data exchange between different DCS software and enterprise systems like ERP and MES, ensuring system interoperability.

7 Pros of DCS

A Distributed Control System (DCS) offers significant benefits for production environments. These systems streamline operations and enhance overall efficiency.

Here are the 7 pros of DCS:

| Benefit | Description |

|---|---|

| Centralized Control | Efficient management from a single point, enabling faster decisions. |

| Enhanced Efficiency | Minimizes downtime and optimizes workflows for higher productivity. |

| Scalability and Flexibility | Grows with your business, adapting to changing needs seamlessly. |

| Improved Safety | Enhances operational safety through precise monitoring. |

| Comprehensive Data Management | Collects and analyzes data for informed decision-making. |

| Enhanced Reliability | Robust design reduces failures, ensuring smooth operations. |

| Regulatory Compliance | Facilitates adherence to industry standards and protocols. |

1. Centralized Control

A DCS offers centralized control that manages multiple processes from a single point. This ensures seamless integration and quicker operational decisions.

2. Enhanced Efficiency

By automating workflows, a DCS significantly improves operational efficiency. It reduces downtime, leading to higher productivity and cost savings.

3. Scalability and Flexibility

A DCS grows as your business grows. It easily integrates new functions without disrupting existing operations, adapting to your changing needs.

4. Improved Safety

In hazardous environments, a DCS enhances safety through real-time monitoring. This minimizes human error and protects both workers and equipment.

5. Comprehensive Data Management

Data management is key to success, and a DCS excels at it. It gathers and analyzes data, providing insights that improve decision-making and operations.

6. Enhanced Reliability

Thanks to its reliable design, a DCS ensures fewer breakdowns and interruptions. This reliability keeps critical systems running smoothly.

7. Regulatory Compliance

A DCS helps meet stringent regulatory standards with ease. It logs and monitors data, ensuring compliance with industry-specific protocols.

3 Cons of DCS

While Distributed Control Systems (DCS) are beneficial, they come with significant challenges. It’s important to understand these drawbacks before committing to a DCS.

Here are the 3 cons of DCS:

1. Initial Cost

Implementing a DCS requires a substantial upfront investment. The costs of hardware, software, and expert services can be a major financial hurdle.

2. Vulnerability to Cybersecurity Threats

DCS systems are vulnerable to cyberattacks due to their reliance on fast communication networks. Safeguarding these systems demands ongoing investment in cybersecurity.

3. Integration Challenges

Integrating a DCS with existing systems can be difficult. Compatibility issues often require expensive customization or even system overhauls.

DCS vs. Programmable Logic Controller Systems

When comparing Distributed Control Systems (DCS) and Programmable Logic Controllers (PLCs), it’s essential to understand their unique strengths and uses in industrial automation.

While both systems play key roles in managing control processes, they differ in complexity, scalability, and integration.

Below is a side-by-side comparison of DCS and PLC systems:

| Feature | DCS Systems | Programmable Logic Controllers (PLCs) |

|---|---|---|

| Control Operations | Optimized for continuous, complex processes | Best for discrete, fast-paced operations |

| Scalability | Highly scalable, suited for large distributed environments | Modular scalability, often used in smaller applications |

| Integration | Seamlessly integrates with various industrial systems | Requires additional modules for integration with other systems |

| Complexity of Control | Executes advanced control strategies via sophisticated algorithms | Focuses on straightforward logic for machinery operation |

| User Interface | Complex interface for detailed process control | User-friendly, simpler interface for direct control tasks |

| Cost Implications | Higher initial investment but lower operational costs over time | Lower initial cost, but can incur higher costs in complex setups |

| Major Industries | Chemical, oil and gas, power generation, pharmaceuticals | Manufacturing, automotive, packaging, material handling |

Conclusion

A Distributed Control System (DCS) plays a vital role in automating complex industrial processes, offering precision, reliability, and scalability.

From real-time monitoring to enhanced safety, DCS ensures seamless operations across industries like manufacturing, energy, and pharmaceuticals.

Understanding the necessary components of a DCS helps you maximize its benefits, enabling smoother workflows and better data management.

Ready to explore how a DCS can transform your business? Take the next step and strengthen your industrial automation strategy today!

Ready to Upgrade Your Control System Knowledge?

Our blog is filled with insights on DCS innovations, and our IT Software Solutions offer expert guidance to maximize your automation potential.

Start enhancing your DCS with Texmg today!

FAQ

What is the Difference Between DCS and PLC?

Distributed Control Systems (DCS) are designed for large-scale process control and automation, while Programmable Logic Controllers (PLC) are suited for discrete control and smaller-scale automation tasks.

What Does DCS Mean?

DCS stands for Distributed Control System, which is a computerized control system used to manage and automate complex industrial processes in sectors like manufacturing, oil and gas, and power generation.

What is the Difference Between DCS and SCADA?

DCS focuses on process control and automation in large-scale industrial operations, whereas SCADA (Supervisory Control and Data Acquisition) systems are used for monitoring, gathering, and analyzing real-time data from industrial processes or equipment.

What are DCS Programs?

DCS programs, also known as control strategies or logic, are software applications developed to control and regulate processes within a Distributed Control System, defining how the system responds to input signals and executes specific actions.